Legs and Aprons

The function of the tools I use and how they work are explained here. Specific tools used are noted in bold.

The leg and apron pieces are first cut to rough dimensions and left to sit overnight. This allows the internal stresses in the wood to relax before they are cut to final dimensions. If the pieces were immediately cut to final dimensions, there is a high probability that the pieces would warp after they were cut.

After resting, the pieces are dimensioned using standard process of jointing one face, planing the other face, cutting to width, jointing edges, and cutting to length. The legs are formed by joining two boards at a 90 degree angle. A locking mitre joint is cut using a special cutting bit on the shaper.

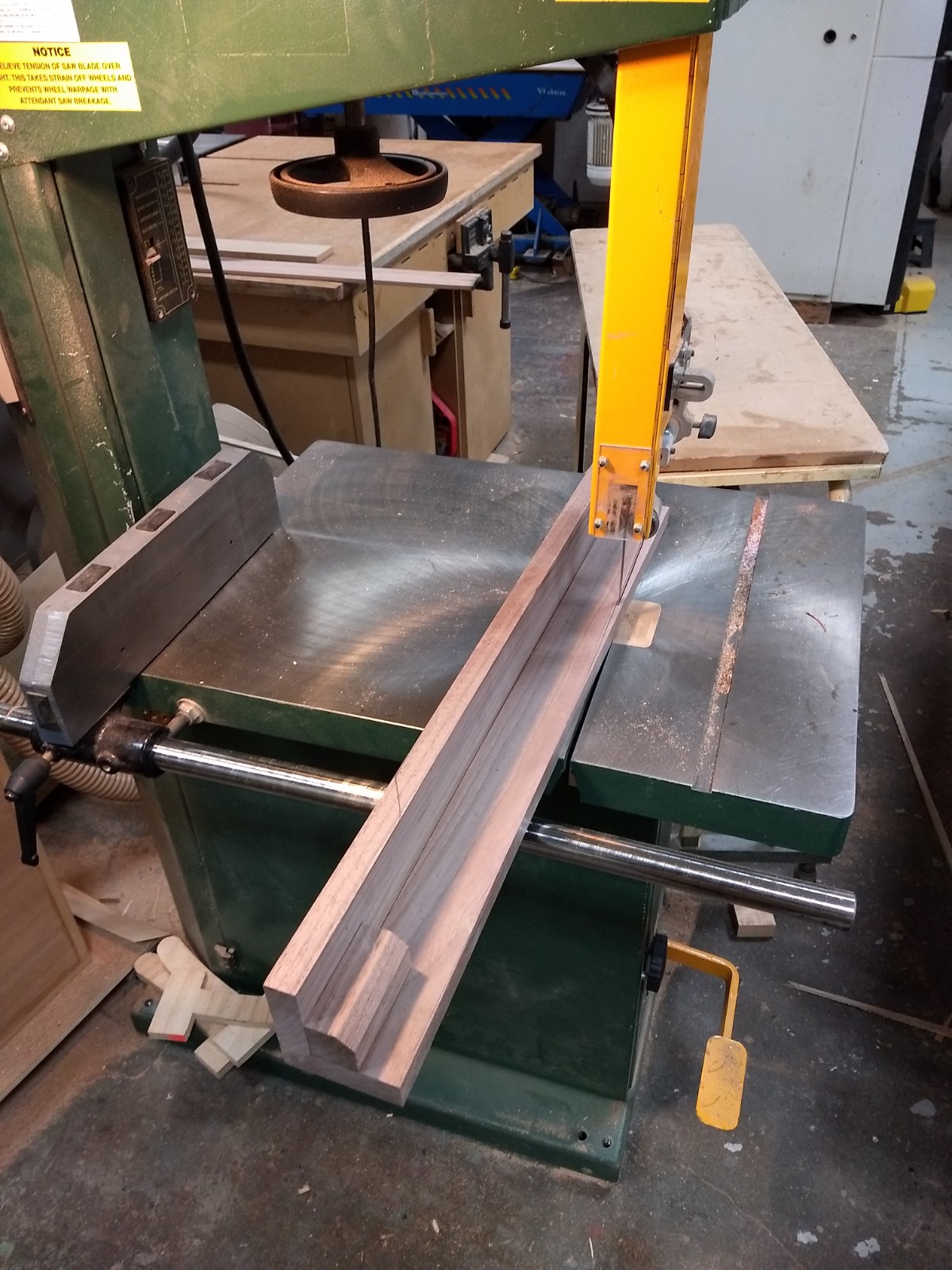

Like the top, the outside edges of the legs have a sweeping arch. The arch is first cut on the band saw, and then the curve is trued and smoothed on the edge sander.